Parameters of the embossed aluminum foil roll Alloy 1100\8011 Temper H22\0\H18 Thickness 0.04--0.25mm Width 200--1300mm Diameter 76\152 Color silver, black, gold, etc Surface treatment printed, coated, etc Custom pattern orange peel, star-struck emboss, etc What is an embossed aluminum foil roll? Aluminum foil shall be annealed and softened before embossi ...

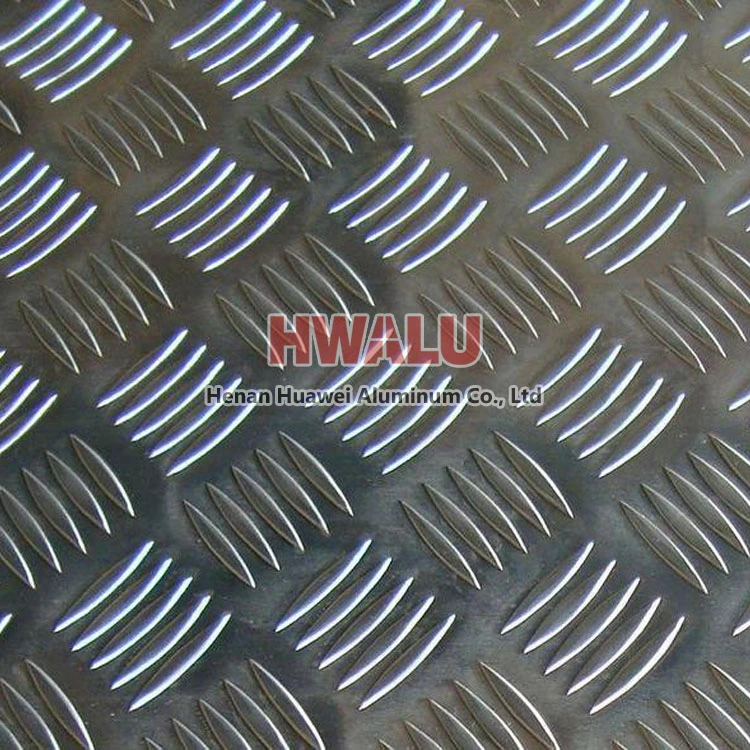

what is diamond embossed aluminum sheet Diamond embossed aluminum sheet is a type of aluminium sheet that has a raised diamond pattern on its surface. This pattern is created by a process called embossing, which involves pressing the aluminium sheet with a patterned roller or die. diamond embossed aluminum sheet Alloy parameters of Diamond embossed aluminum sheet The most commonly used alloy for the dia ...

Alloy 3003 Thickness 0.2-1.0mm Width 800-1250mm Application Usually used for refrigeration equipment and pipe insulation, such as refrigerator, air conditioner, the series of products because of good thermal conductivity of the special pattern, thermal performance The finish of stucco embossed aluminum plate is achieved by embossing roller processing of natural finish material. Thi ...

Embossed aluminum sheet is also called stucco aluminum sheet. It is based on aluminum plate. After calendering, various beautiful patterns are formed on the surface of aluminum sheet. Therefore, it is called embossed aluminum sheet in the industry. This product is widely used and is common in product packaging and architectural decoration. Why embossed aluminum sheet is used in refrigerator liner and what advanta ...

1-Architectural decoration: Embossed aluminum can be used as decorative materials such as building walls, ceilings, doors and windows, partitions, etc., providing aesthetics, durability and fire resistance. 2-Home decoration: Embossed aluminum can be used as interior decoration materials such as furniture, suspended ceilings, partitions, etc., providing aesthetics, easy cleaning and moisture resistance. 3-A ...

1. Aluminum has better heat transfer performance and ranks among the best among metals; 2. A dense oxide film can be formed on the surface of aluminum, which has good corrosion resistance; 3. The proportion of aluminum is relatively small, and the weight of the manufactured equipment is relatively light; 4. Embossing can increase the heat transfer area and improve the heat transfer efficiency. The e ...

First, in terms of refrigeration speed: according to the principle of physics, the thermal conductivity of aluminum is 237W/mK, and the thermal conductivity of iron is 80W/mK. The greater the value of the thermal conductivity, the better the thermal conductivity, the faster the cooling speed under the same conditions, and the better the refrigeration effect. The embossed aluminum plate evaporator, refrigeration s ...

The concept of orange peel embossed aluminum Embossed aluminum coil/aluminum plate (patterned aluminum plate) is an aluminum product with a pattern formed on the surface after calendering on the basis of aluminum plate. There are mainly orange peel, diamond, bean pattern, Samsung, hemispherical and other patterns, which are commonly used in packaging, construction, curtain walls, refrigerators, air conditioners, ...

Parameters of the embossed aluminum foil roll Alloy 1100\8011 Temper H22\0\H18 Thickness 0.04--0.25mm Width 200--1300mm Diameter 76\152 Color silver, black, gold, etc Surface treatment printed, coated, etc Custom pattern orange peel, star-struck emboss, etc What is an embossed aluminum foil roll? Aluminum foil shall be annealed and softened before embossi ...

Embossed aluminum sheet is a highly decorative aluminum sheet product, which is usually used in building exterior walls, roofs, interior decoration, billboards, body shells, furniture production and other fields. It achieves a variety of decorative effects by machining the aluminum plate into a surface with different patterns. Common embossed aluminum plates include rolling flowers, water ripples, and squares. ...

stucco aluminum coil also called stucco embossed aluminum coil Embossed aluminum coil, after the process of embossing, cutting, oxidation will form the surface with a dense layer of aluminum oxide protective film. And It has obvious below advantages such as acid-corrosion-resistance, long-lasting shine, beautiful patterns, anti-corrosion performance and stability, strong adhesion, impact resistance, non-toxic ...